Our History

A Passion for Innovation

We founded RubberForm Recycled Products, LLC to transform recycled tire rubber and recycled plastic into high-performance, American-made safety and risk mitigation products. This vision for RubberForm came from Bill Robbins’ deeply personal entrepreneurial journey. And his business background and commitment to sustainability fueled every step.

2004–2005: The Pivot Point

In late 2004, Bill pursued the purchase of a bankrupt rubber molding business in Upstate New York. Negotiations began in November 2004 and by February 2005 the bank was ready to accept the offer. However, in April 2005, another buyer outbid them, and the original owner proposed a 50:50 partnership. Unwilling to share control or compromise his vision, Bill walked away and instead formed RubberForm that same month.

By November 2005, RubberForm had finalized its business plan, secured equipment, and completed financing to begin operations.

2006: Plant Opens in Lockport, NY

In January 2006, RubberForm took possession of its facility on Michigan Street in Lockport. The team began renovations to create a clean, well-ordered plant aligned with Bill’s 5S-driven commitment to excellence.

On October 19, the company manufactured its first compression-molded sign base for its first customer, Wegmans Food Markets of Rochester NY, a past client of Bill’s. The company held its grand opening on December 7.

2007: Product Expansion Begins

- February 8: The first wheel stop was produced.

- March 23: First wheel stop shipment.

- May 31: Shipped the first sign base order to Wegmans.

- November: RubberSidewalks launched and began shipping.

2008–2009: Market Crash and Regrouping

The 2008 stock market crash shook the economy. In August 2009, RubberForm’s bank called its commercial loans. Despite this blow, the company regrouped, tightened operations, and pressed forward.

2010–2012: Strategic Expansion and Major R&D Investment

In May 2010, RubberForm acquired a die-cutting business to produce loading dock bumpers for the second-largest dock manufacturer in North America. That division ceased production in December 2012 as recycled scrap conveyor belts were not its core business and did not align with its vision.

In January 2012, RubberForm began developing a new rubber-plastic composite material through the ambitious “Davis Project,” investing over $3 million in R&D across four years. This effort aimed to pioneer automated manufacturing using blow molding, compression molding, and robotic automation technologies. Despite initial technical successes, the process lacked consistent material flow, leading to the project’s shutdown in January 2016. Despite that setback after 4 years of R&D, we had a new target: a custom-made injection molding press for RubberForm development of thick-walled injection molded products.

In December 2011, Bill bought out co-founder Deborah Robbins, consolidating ownership.

2014–2016: Transition to Injection Molding

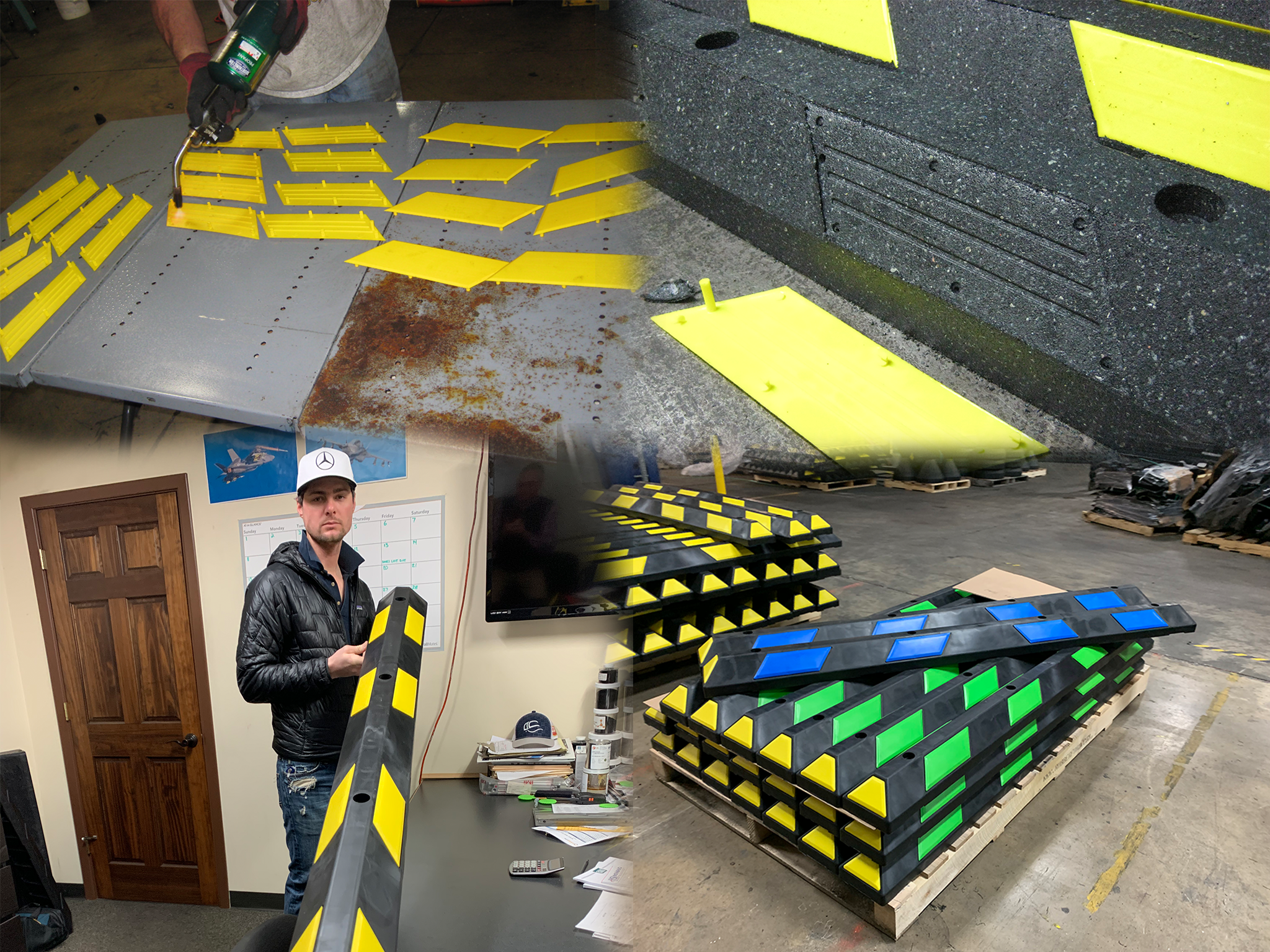

In February 2014, the Dolci system came online to produce compression-molded blocks for RubberForm’s Patented Trackout Control Mats.

With lessons learned from the Davis Project, RubberForm began shifting to high-tonnage injection molding in 2016. A new generation of injection molds and composite recycled materials were developed, marking a strategic pivot in product design and RubberForm’s future.

2019: Building the Family Part of the Business

In February 2019, Jeffrey and Jacob Robbins joined the company full-time. Jeff drove with his father from California (a bucket-list trip for Bill) and then with Jake from Austin to Buffalo.

That November, RubberForm successfully molded its first Next Generation Wheel Stop.

2020: Pandemic Pressure and Innovation

On March 18, 2020, COVID-19 forced all sales and customer service staff to work remotely. Operations remained open, as RubberForm was deemed essential.

- March: First shipments of the Next Generation Wheel Stop.

- June: Product redesign to resolve engineering issues.

- September: Redesigned version shipped to customers.

- November: Successfully injection molded the Next Generation Speed Cushion; field testing began.

Wheel Stop Innovation Timeline Highlights

- Early 2000s: First compression-molded wheel stop with in-mold road tape polygons.

- Circa 2010: Transitioned to injection-molded plastic polygons after discovering foreign competitors had government subsidies.

- Innovated corona-treatment process for durable adhesion of plastic polygons.

- 2012 onward: Continuous R&D to address installation, color customization, drainage, and environmental sustainability.

- Developed lighter, stronger wheel stops using proprietary composite materials and injection molding technologies.

- Added a RubberForm invention, our patented features like snap-in replacement polygons, custom printed polygons, custom colors and drainage channels.

2022: Thick-Walled Profile Extrusion Development

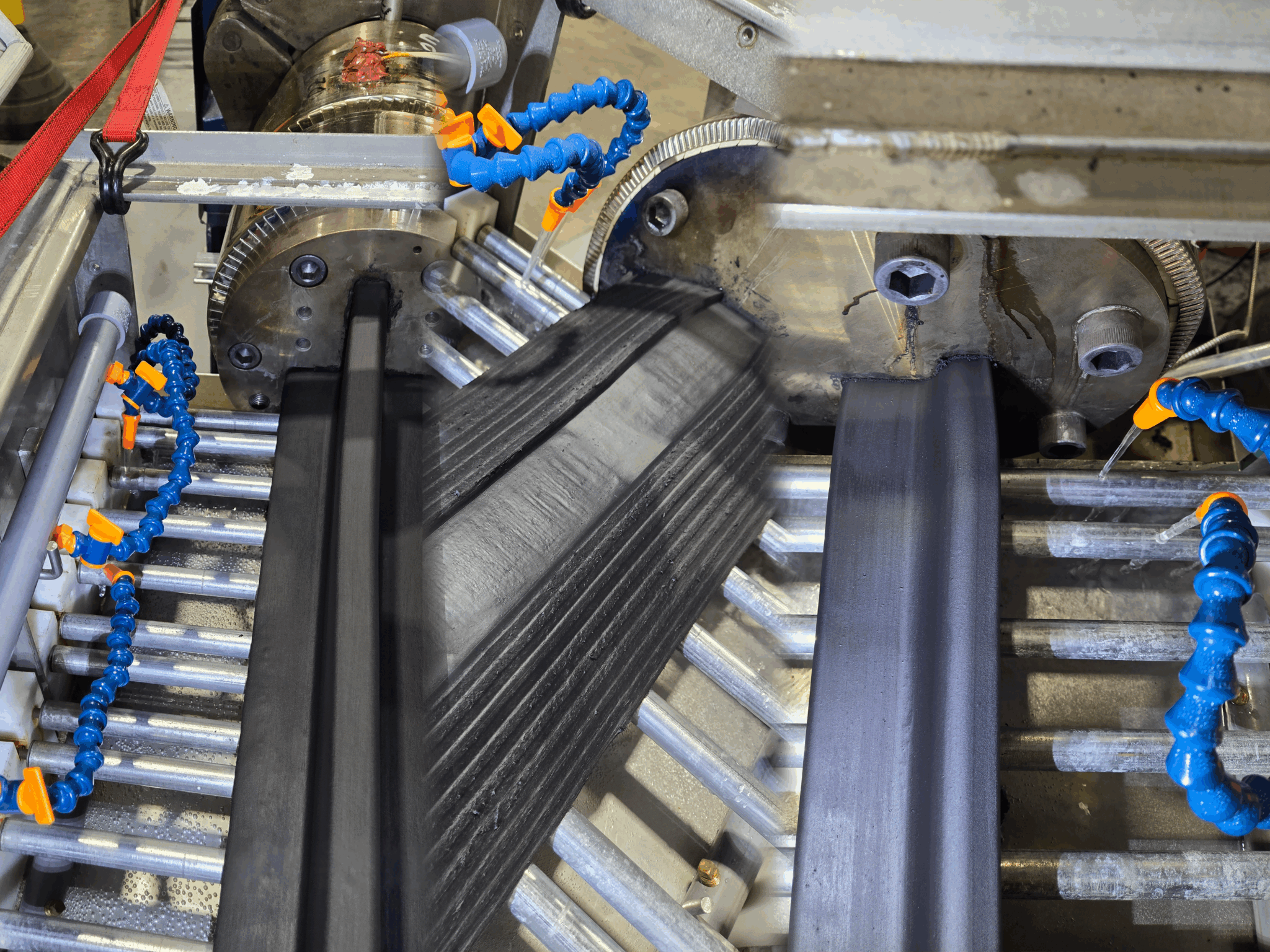

RubberForm couldn’t keep up with growing demand for its rubber products without moving to new profile extrusion technology. From 2014 to 2018, Bill met with national profile extrusion experts to determine if what he envisioned could be produced; they all said it could not be done. But a Robbins always finds a way to innovate. Bill first hired two renowned profile extrusion experts and they both worked on trying to extrude a thick-walled product. They failed. Then RubberForm invested in its own, in-house multi-million-dollar R&D profile extrusion line. We hired a seasoned engineer who had no experience in profile extrusion (and no preconceived pretenses that “it could not be done”). After all, “Can do” is what RubberForm has done since its founding in 2005. With Bill’s tenacity and will to prove these experts wrong, RubberForm successfully extruded its first thick-walled part about a year later. And in the fall of 2024, we placed an order for the country’s largest profile extrusion system with extrusion capabilities of 24” wide and 12” tall.

Where We Stand Today

RubberForm is now one of only two U.S.-based wheel stop manufacturers. Our raw materials are 100% recycled and sourced domestically. We hold many U.S. and international patents on our injection-molded and extruded products, which stands as a testament to American engineering, innovation, and Bill Robbins’ relentless pursuit of excellence.

Bill’s leadership along with his two sons, Jeff and Jake, defined by hands-on problem solving, plant-floor involvement, and a passion for process improvement—continues to drive RubberForm forward. His mission has never changed: to create a winning company that leads with sustainable materials, superior design, and U.S.-based manufacturing.