- Construction

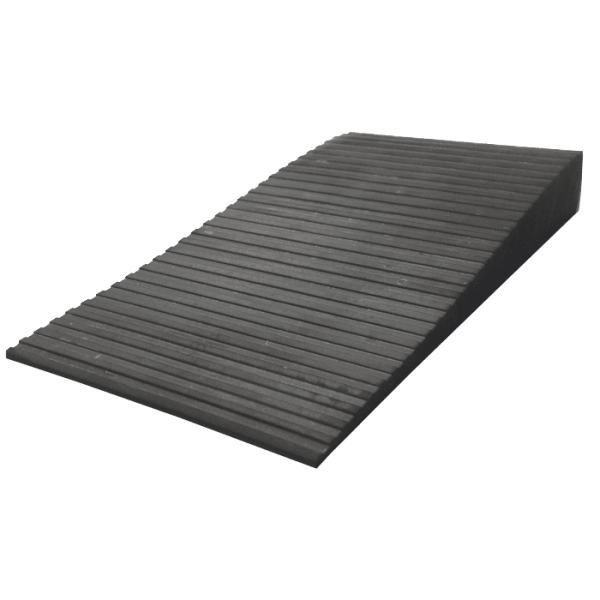

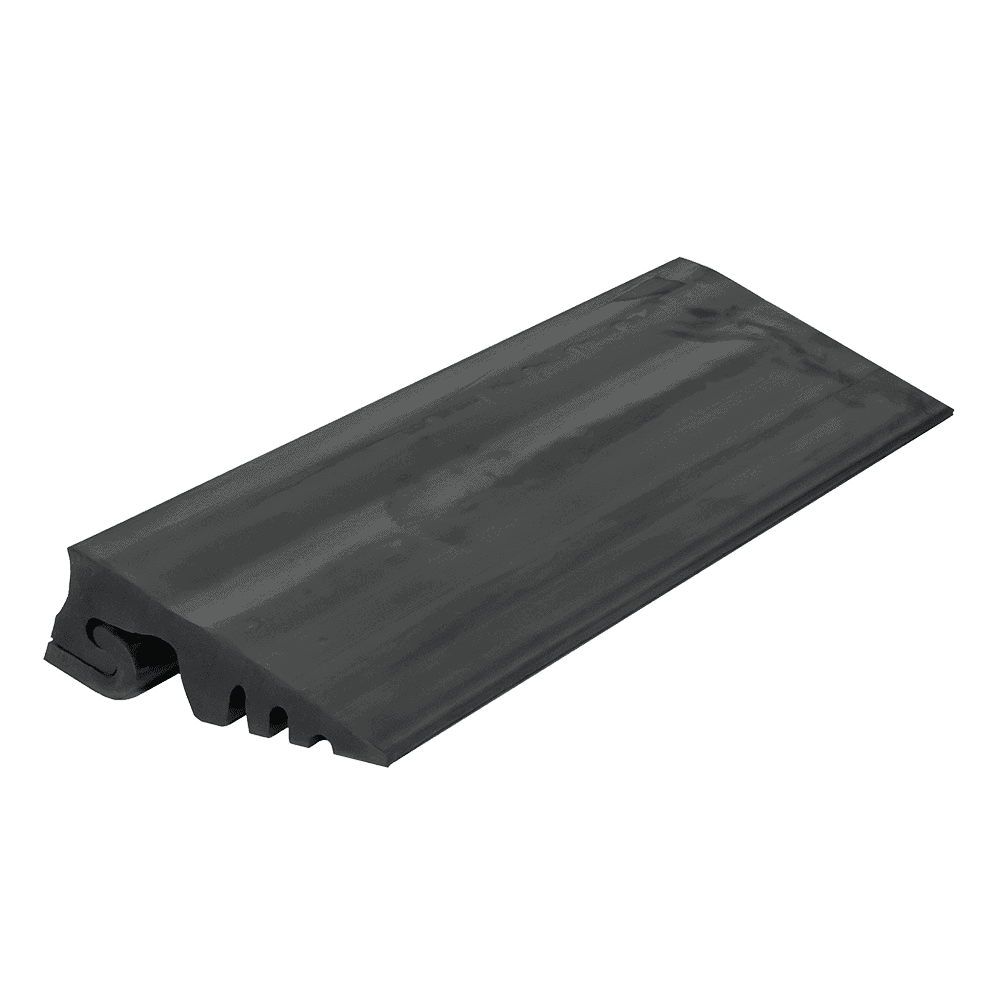

Wedge Ramps

Product Description

Our RubberForm Wedge Ramps are an effective alternative to using gravel or asphalt to transition over uneven surfaces during a construction project.

Our 100% American recycled composite ramps are easy to install, just as easy to remove and relocate, and won’t crack, crumble or corrode. They can withstand heat, cold, rain, ice, and snow. And of course, high traffic of heavy vehicle loads.

Keep your workers safe and your project on time.

Specifications:

- Multiple sizes available 3/4” H x 1” H 1-1/2””H x 10”W x 8’’L 1-3/4” 2”H x 11”W x 10’L 2-1/2”H 3”H 3-1/2”H

- Extruded in 8-foot lengths or custom lengths available upon request

- Will not damage concrete, pavement, or tires

- High load-bearing capacity

- Made in the USA with 100% recycled composite material

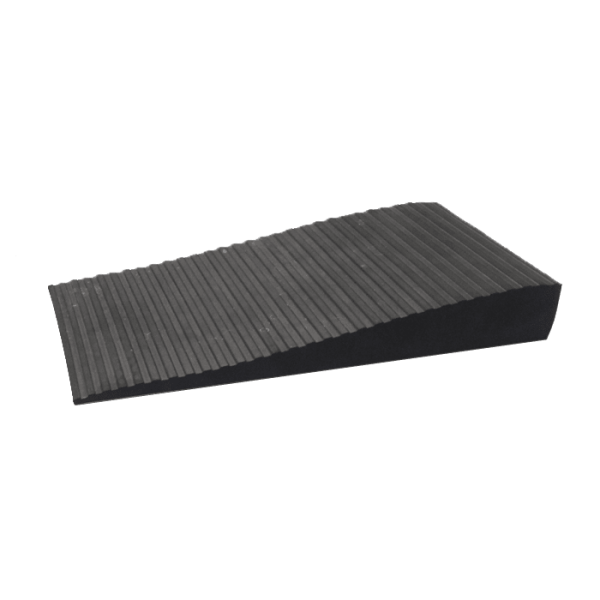

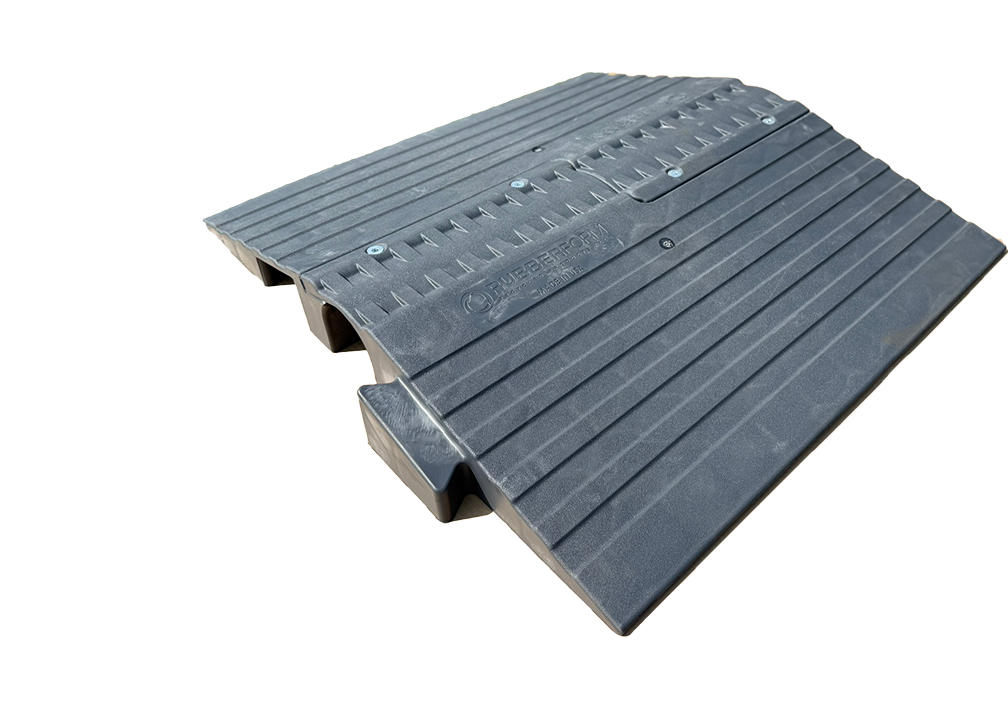

Product Description

Traditional methods of building wedge ramps waste time, manpower, resources, and money that would be better spent delivering your project on time and under budget. Our RubberForm Wedge Ramps are blessedly simple: no digging, no gravel, no rubber pour-n-place, no asphalt, no constant maintenance, and no messy cleanup.

Installation is easy: place the ramp where you want it. Removal is just as simple. Our 100% American recycled composite ramps are durable: no chipping, warping, or spalling due to heavy use or inclement weather. That means you can use and reuse our ramps at jobsite after jobsite for decades.

Keep your workers safe and help clean up America’s backyard while you do it!

Models

RF-WGRP1.25.10F

- 1¼”H x 10”W x 10’L

RF-WGRP2.11.10F

- 2”H x 11”W x 10’L

Key Features

- Easy to install and transport

- Will not damage concrete, pavement, or tires

- High load-bearing capacity and safely absorbs impacts

- Will not tear, chip, crack, or spall

- Resistant to temperature variations, UV light, oils/fuels, salts, and moisture

- Made in the USA with 100% recycled composite material